WE RESEARCH.

Professional teamwork, cooperation in national and international research projects and standardisation committees, state-of-the-art laboratories, and dedicated quality assurance concepts, guarantee the FEhS Institute conducts practice-oriented research at the highest level – for our members and partners, companies from all over the world, and public clients.

here.

OUR LABORATORIES.

In the building complex of the FEhS Institute, we have laboratories for cement, concrete, chemistry, mineralogy, slag metallurgy (including a mobile laboratory), transport construction, and fertilisers, all equipped with cutting-edge technology and experienced personnel, where we conduct both publicly funded and privately contracted research. And we are frequently involved in series of international tests.

In our laboratories, which are accredited by the German accreditation body DAkkS, we also act as a recognised institute, above all for testing relating to construction materials, road construction and environmental matters.

Click here for a selection of research projects of the FEhS Institute.

Home-made high-tech: for us, practical applications are the driving force behind innovative research. That is how we keep on developing pioneering processes:

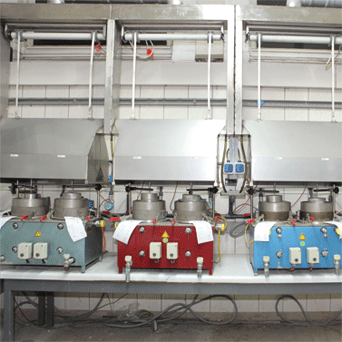

TRANSPORT CONSTRUCTION EXAMPLE: Steam test according to

DIN EN 1744-1

DIN EN 1744-1

Way back in the 1980s, initially as a laboratory procedure, we developed a steam test for testing the volume stability of steelworks slag, which was to be used as aggregate in road construction. This determines the increase in volume of the slag resulting from the reaction between free lime or magnesium oxide and moisture. We have continuously developed the process further, and brought it to the stage of standardisation. Then as now, it represents the state of the art.

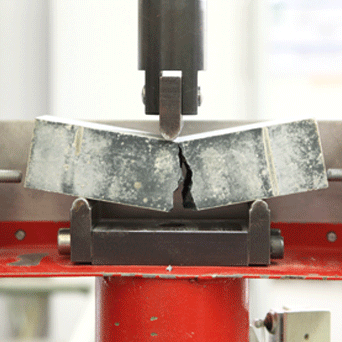

TRANSPORT CONSTRUCTION EXAMPLE: Vibration hammer test according to DIN EN 13286-4

The Proctor test according to DIN EN 13286-2 was long considered the standard for testing the compaction of construction material mixtures. In cooperation with the IKM Institute for Lime and Mortar Research in Cologne, the FEhS Institute developed a new process. It does not only deliver exact measurement results, but also compacts in compliance with in-situ requirements, and is simple and time-efficient to perform.

Furthermore, we at the FEhS Institute work together as partners with members, customers and public authorities in numerous national and international research projects:

SLAG METALLURGY EXAMPLE

In addition to various studies on conditioning, solidification, recycling, recovery of valuable materials and the environmental compatibility of slags of all kinds, research is increasingly focusing on the decarbonisation of the steel industry. In the process, completely chemically and mineralogically altered by-products are formed. The joint project SAVE CO2, for example, aims to develop latent hydraulic binders, comparable to today’s blastfurnace slag, or alternative pozzolans on the basis of new slags, especially for cement production.

ENVIRONMENT EXAMPLE

The experts at the FEhS Institute are contact partners for the environmental authorities when it comes to the development of regulations. Current examples include the “Framework Directive for Alternative Construction Materials and Soil Protection” from the Federal Ministry for the Environment (BMUB), a harmonised German “Directive on Systems for Handling Water-Polluting Substances”, and at a European level, the harmonisation of test methods for the Construction Products Directive (CPD).

CEMENT AND

CONCRETE EXAMPLE

CONCRETE EXAMPLE

The requirements for cement and concrete are increasing. Knowledge of the chemical, physical and ecological properties of these construction materials and the ground granulated blast furnace slag they contain is therefore of great importance. Our research work on the early strength of blast furnace cements has helped to ensure that most CEM III/A blast furnace cements (with max. 65% ground granulated blast furnace slag) are already categorised as strength class 43.5 N (instead of 32.5 N).

FERTILISER EXAMPLE

A test with fertilisers made from ferrous slag has been ongoing in St. Peter since 1954, confirming the positive effect on plants and ensuring groundwater protection. A test started in Rösrath in 1990 has revealed that converter lime is an effective agent preventing the acidification of the soil even in lower layers. Also in the future, both test series will be performed under the supervision of the FEhS Institute.